See How We Restore Sewer Lines Without Digging Through Floors or Landscaping

If your cast iron sewer pipes are failing, backing up, or corroding beneath your home, you’re probably dreading the idea of digging through floors or tearing up your landscaping. Fortunately, there’s a faster, cleaner, and more cost-effective solution: trenchless pipe lining.

At Trenchless Pipe Lining, we specialize in no-dig sewer repair across Dallas, Austin, and other Texas cities using CIPP (Cured-In-Place Pipe) and epoxy lining technologies. Here’s a clear, step-by-step breakdown of how our pipe lining process works — and how it compares to traditional pipe replacement.

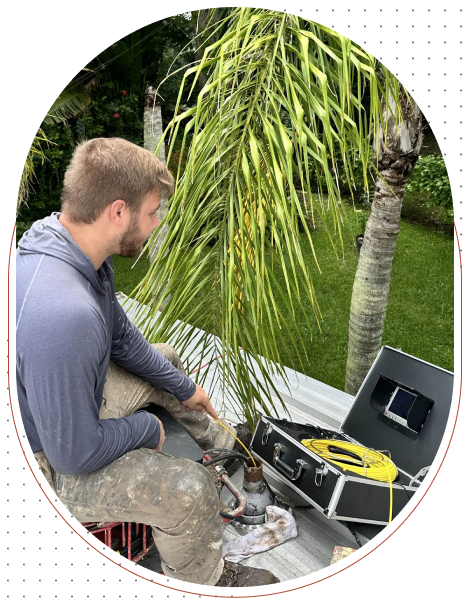

Step 1: Video Inspection and Assessment

We begin by inserting a high-definition video camera into your existing pipe system to assess its condition. This allows us to identify cracks, blockages, rust, or tree root intrusion, and determine if trenchless lining is the right fit. We also measure the total length and diameter of the pipe to prepare for the cleaning and lining process.

Our inspection also reveals whether your pipes need minor spot repairs, or a full lining — and helps us recommend the best method based on age, material, and damage level.

Step 2: Cleaning the Pipe Interior

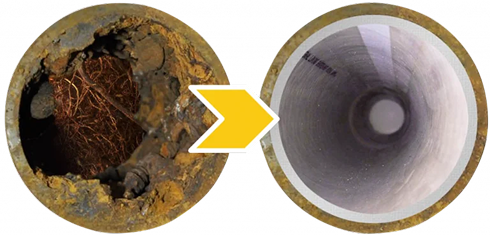

Before lining can begin, the inside of the pipe must be thoroughly cleaned. This is one of the most important steps, as proper surface preparation ensures that the epoxy bonds correctly to the pipe walls.

Step 3: Filling Gaps and Voids (If Necessary)

If the inspection reveals large voids or holes in the pipe, we inject epoxy into those areas under camera supervision. This reinforces structural integrity and ensures a uniform surface for lining.

This step is especially important in older cast iron pipes that have experienced decades of corrosion and erosion at the bottom of the line.

Step 4: Pipe Lining Installation (3 Options)

We use three industry-approved trenchless pipe lining methods based on your specific situation:

This method is ideal for homes where pipe access is limited. We use a rotating nozzle to apply a uniform epoxy layer inside the cleaned pipe. It’s especially effective for vertical stacks and tight interior lines.

CIPP involves inserting a resin-saturated felt liner into the pipe and curing it using steam or hot water. This method works best for long, straight sewer lines with moderate access points.

A newer option, UV-cured lining uses light to harden the liner quickly. It’s often used in commercial settings or areas with strict time constraints due to its rapid cure time.

Epoxy Pipe Lining Process:

Epoxy Pipe Lining Process:

1

Dry the pipe using high-pressure airflow.

2

Prepare the epoxy mixer, pump, hoses, and nozzle.

3

Insert the nozzle and inspection camera to the far end of the pipe.

4

Slowly pull back while rotating the nozzle and applying epoxy.

5

Allow to cure for 1–4 hours.

6

Apply a second layer for added durability.

Step 5: Final Video Inspection and Warranty

Once the epoxy or liner has cured, we perform a final video inspection to confirm the repair. You’ll receive a digital copy of the video, a detailed invoice, and our 50-year transferable warranty — giving you peace of mind and added resale value for your home.

What You Receive After the Job

With every trenchless pipe lining service, you get:

We make the process simple, well-documented, and built to last.

Why Pipe Lining Is a Smarter Long-Term Investment

Beyond the immediate benefits, trenchless pipe lining offers long-term advantages over traditional repair methods:

Thanks to updated infrastructure and a transferable warranty.

In the future — epoxy-lined pipes are seamless and resistant to corrosion and root intrusion.

Since no demolition or soil removal is needed.

No need to replace marble, tile, or woodwork.

Pipe Lining vs. Traditional Pipe Replacement

Still wondering how this compares to full excavation? Here’s what most homeowners don’t realize:

Pipe Excavation & Replacement

Trenchless Pipe Lining

In short: trenchless lining offers massive savings — in time, cost, and disruption.

Why Choose Trenchless Pipe Lining?

Our team has installed thousands of feet of pipe lining across Texas using the most trusted epoxy and CIPP technologies. We back every project with a 50-year warranty, high-definition video proof, and clear communication from start to finish.